In the vast realm of career options, there are certain occupations that stand out for their unique blend of technical skill, versatility, and craftsmanship. One such profession is that of a millwright – a skilled tradesperson who possesses a wealth of knowledge in mechanical systems, machinery installation, and maintenance. While the term millwright might not be as widely recognized as other occupations, their expertise has been instrumental throughout history in a wide range of industries, from manufacturing and construction to power generation and beyond. In this article, we delve into the intricate world of millwrights, exploring their role, skills, and the opportunities they bring to the dynamic job and career sector – shedding light on a profession well worth understanding and appreciating.

Millwrights: An Introduction to a Versatile Trade

What Is a Millwright?

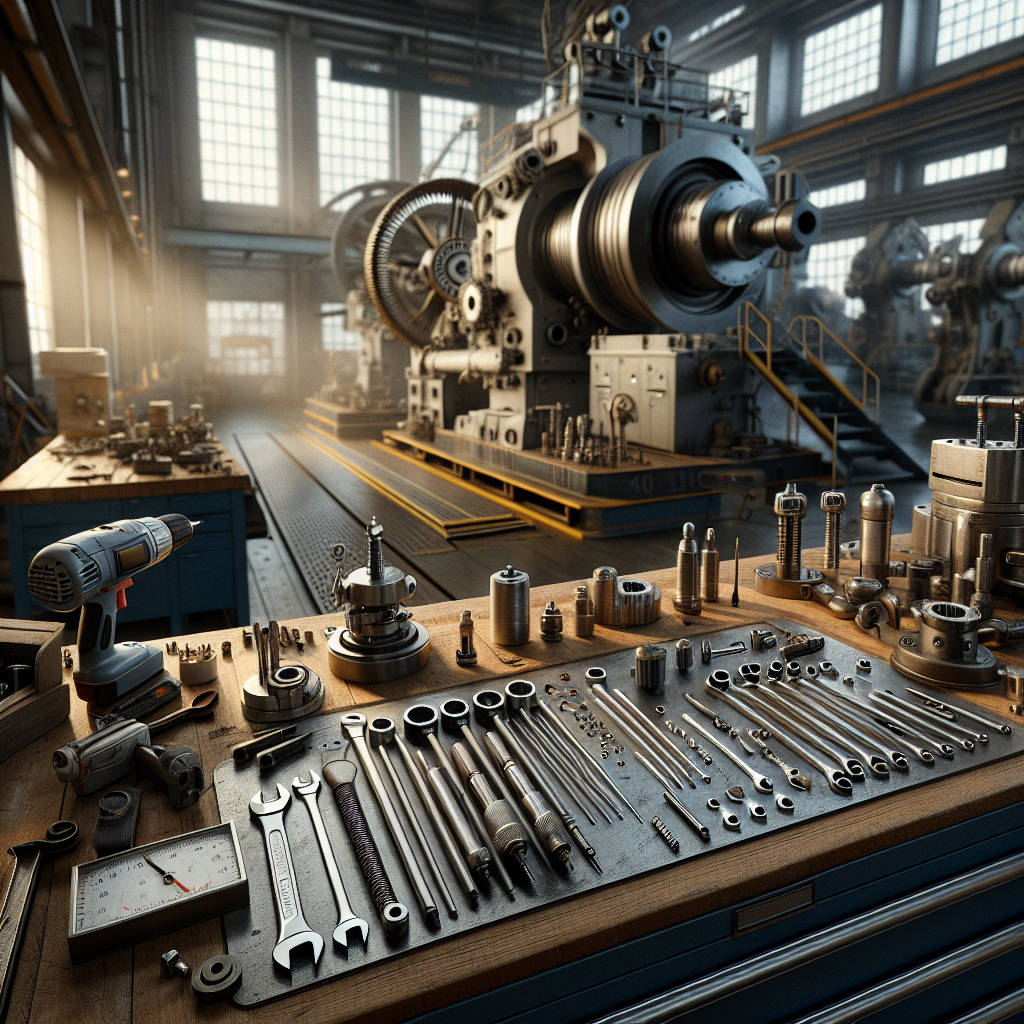

Millwrights are skilled craftsmen who install, repair, and maintain heavy machinery and equipment in various industries. They play a crucial role in ensuring the smooth operation of factories, power plants, construction sites, and other industrial settings. With their versatile skills and extensive knowledge, millwrights are highly sought-after professionals in the job market.

Skills and Expertise

Millwrights possess a diverse skill set that includes mechanical, electrical, and hydraulic knowledge. They are well-versed in interpreting blueprints and technical drawings, dismantling and assembling machinery, aligning and leveling equipment, and troubleshooting mechanical issues. These professionals are masters of precision, as they must ensure that every component of a machine functions flawlessly in order to maintain optimal productivity and safety.

Work Environment

Millwrights work in a variety of settings, ranging from manufacturing plants to construction sites. They may be exposed to hazardous materials, extreme temperatures, and noisy environments. These professionals are trained to comply with strict safety regulations and wear protective gear such as hard hats, safety glasses, and gloves. Additionally, they often work in teams and collaborate with engineers, project managers, and other skilled tradespeople to complete projects efficiently and effectively.

Career Outlook

The demand for millwrights is expected to remain steady in the coming years. As industries continue to evolve and modernize, there will be a continuous need for skilled professionals to install and maintain advanced machinery. According to the Bureau of Labor Statistics, the median annual wage for millwrights was $54,740 in 2020, with the top 10% earning more than $87,970. With the right training and experience, millwrights can pursue various career paths, including project management, equipment sales, or even starting their own businesses.

| Industry | Percentage of Employment |

|---|---|

| Manufacturing | 34% |

| Construction | 20% |

| Power Generation, Transmission, and Distribution | 12% |

| Metalworking Machinery Manufacturing | 7% |

| Food Manufacturing | 5% |

The Role and Responsibilities of a Millwright

Overview

A millwright is a skilled tradesperson who specializes in installing, maintaining, and repairing industrial machinery and equipment. They are typically employed in manufacturing plants, construction sites, and power generation facilities. Millwrights play a vital role in ensuring the smooth operation of machinery, which is crucial for the productivity and profitability of various industries.

Responsibilities

The primary responsibilities of a millwright include assembling, installing, and dismantling machinery and equipment according to blueprints, diagrams, and specifications. They are skilled in using a variety of hand and power tools to align, level, and secure machinery components. Millwrights are also well-versed in troubleshooting and performing routine maintenance to detect and rectify any issues that could potentially disrupt the operation of machinery. Additionally, they are responsible for inspecting equipment, ordering replacement parts, and ensuring compliance with safety regulations.

Skills and Qualifications

To excel as a millwright, one must possess a unique set of skills and qualifications. Strong mechanical aptitude and problem-solving abilities are essential, as millwrights often encounter complex machinery and intricate systems. They should have a thorough understanding of technical drawings and be able to work with precision and attention to detail. Additionally, physical stamina and dexterity are vital, as millwrights are often required to work in physically demanding environments. Strong knowledge of safety protocols and the ability to work collaboratively with other tradespeople are also crucial qualities for success as a millwright.

| Statistic | Data |

|---|---|

| Total Employment | 74,600 |

| Job Outlook | +8% (Faster than average) |

| Median Annual Wage | $54,220 |

| Industries with Highest Employment | Construction; Machinery Manufacturing; Specialty Trade Contractors |

Education and Training Requirements for Millwrights

Education and Training Requirements

Millwrights are highly skilled individuals who are responsible for the installation, maintenance, and repair of machinery and equipment in various industrial settings. To become a millwright, a combination of formal education and on-the-job training is typically required.

Education: Most millwrights start their training by completing a high school diploma or equivalent. While not always required, it is beneficial to have a strong foundation in math, science, and mechanical or industrial technology courses. Additionally, vocational or technical schools offer millwright programs that provide more in-depth training in areas such as blueprint reading, welding, hydraulics, and electrical systems.

Apprenticeship: Once the initial education is completed, aspiring millwrights commonly enter into an apprenticeship program. These programs, which typically last four to five years, combine classroom instruction with hands-on training. Apprentices learn from experienced millwrights and gain practical skills in areas such as precision alignment, welding, and troubleshooting. Some states may require individuals to complete an approved apprenticeship program to become licensed millwrights.

Skills and Qualifications

- Strong mechanical aptitude and problem-solving skills

- Ability to read and interpret blueprints and technical manuals

- Proficiency in using various hand and power tools

- Knowledge of safety regulations and procedures

- Good physical stamina and dexterity

- Effective communication and teamwork skills

Continuing Education and Certification

Millwrights can further enhance their knowledge and skills by pursuing additional education and certification. This can involve attending workshops, seminars, or specialized training programs related to specific industries or technologies. The International Maintenance Institute (IMI) offers certifications that can validate a millwright’s expertise, such as the Certified Maintenance & Reliability Technician (CMRT) and the Certified Maintenance & Reliability Professional (CMRP) certifications.

Continuing education and staying up to date with the latest industry advancements are essential for millwrights to remain competitive in their field. With the constant evolution of technology and machinery, millwrights must continuously adapt and expand their knowledge to effectively perform their job duties.

Skills and Qualities Every Millwright Should Possess

Millwrights play a crucial role in the job industry, particularly in the field of industrial machinery installation, maintenance, and repair. To excel in this profession, certain skills and qualities are essential. Here are some key attributes that every millwright should possess:

Technical Knowledge: A millwright must have a strong foundation in mechanical principles and be familiar with various types of machinery and tools. They should be well-versed in reading and interpreting blueprints, schematics, and technical manuals. Additionally, millwrights should stay updated with the latest advancements in technology and industry standards.

Problem-Solving Abilities: Millwrights often encounter complex issues while troubleshooting and repairing machinery. They must possess excellent problem-solving skills to diagnose the root cause of malfunctions and develop effective solutions. Additionally, being able to think critically and analytically helps millwrights make informed decisions in time-sensitive situations.

Physical Stamina and Dexterity: Millwrights engage in physically demanding work that often involves heavy lifting and manual labor. They must have the physical stamina to handle long hours on their feet and the strength to maneuver heavy machinery and equipment. Moreover, millwrights need to possess excellent hand-eye coordination, agility, and precision to perform intricate tasks.

Additional Skills and Qualities:

In addition to the aforementioned core attributes, successful millwrights have a few extra skills and qualities that enhance their performance in the job industry. These include:

– Attention to Detail: Millwrights should have a keen eye for detail, as even the smallest oversight can lead to significant issues with machinery. Paying close attention to measurements, alignments, and safety protocols is vital to ensure proper functioning and prevent accidents.

– Communication Skills: Effective communication is crucial for millwrights, as they often collaborate with other professionals such as engineers, project managers, and clients. Clear and concise communication ensures that everyone involved understands the requirements, objectives, and progress of the project.

– Adaptability: The job of a millwright can involve working in diverse environments, such as construction sites, factories, or industrial facilities. Millwrights must be adaptable and able to adjust to different working conditions and schedules.

To summarize, millwrights should possess technical knowledge, problem-solving abilities, and physical stamina. Additionally, attention to detail, effective communication skills, and adaptability are valuable assets in this career. Mastering these skills and qualities enables millwrights to excel in their profession and contribute to the smooth functioning of industrial machinery.

Career Paths and Opportunities in the Millwright Industry

Career Paths in the Millwright Industry

Millwrights are skilled trade professionals who install, repair, and maintain machinery in various industrial settings. They play a crucial role in ensuring the smooth operation of heavy machinery, such as conveyor systems, turbines, and manufacturing equipment. A career in the millwright industry offers a wide range of opportunities and paths for growth and advancement.

Apprenticeship Programs: Many individuals interested in becoming millwrights start their careers by joining apprenticeship programs. These programs provide a combination of classroom instruction and on-the-job training, allowing aspiring millwrights to learn the necessary skills and gain hands-on experience. During the apprenticeship, individuals typically learn about blueprint reading, welding, alignment techniques, and safety protocols.

Opportunities and Advancement

Once individuals have completed their apprenticeship, they can explore various career paths within the millwright industry. Some common opportunities include:

- Industrial Maintenance: Millwrights can work alongside maintenance teams in industrial facilities, performing routine equipment inspections, diagnosing issues, and carrying out repairs and maintenance tasks. This role allows millwrights to develop specialized expertise in maintaining specific types of machinery.

- Construction: Millwrights can also work in the construction industry, overseeing the installation and assembly of machinery and equipment at construction sites. This field offers opportunities to work on large-scale projects, such as power plants, refineries, and manufacturing facilities.

- Supervisory and Management Roles: With experience and additional training, millwrights can advance to supervisory or management roles. These positions involve overseeing teams of millwrights, coordinating projects, and ensuring the successful completion of tasks.

Industry Outlook and Job Demand

The millwright industry offers excellent job prospects in the USA, with a high demand for skilled professionals in various sectors. According to the Bureau of Labor Statistics, the employment of millwrights is projected to grow by 8% from 2020 to 2030, which is faster than the average for all occupations. This growth can be attributed to the need for continuous maintenance and upgrading of machinery across industries, as well as the retirements of current millwrights.

Data: Average Annual Salary

| Industry | Annual Salary |

|---|---|

| Manufacturing | $58,290 |

| Construction | $58,630 |

| Power Generation | $65,600 |

These figures highlight the potential earning opportunities within the millwright industry. Remember, salaries may vary based on factors such as location, experience, and specialization.

Advice for Success in the Millwright Profession

Millwright Definition

A millwright is a skilled tradesperson who specializes in the installation, maintenance, and repair of machinery and equipment in various industries. These professionals work primarily in manufacturing plants, construction sites, and power generation facilities. Millwrights are responsible for assembling, dismantling, and adjusting machinery according to blueprints, specifications, and safety standards.

Key Skills and Qualifications

In order to succeed in the millwright profession, there are certain skills and qualifications you should possess:

- Mechanical Aptitude: Millwrights must have a solid understanding of mechanical systems and be able to troubleshoot and repair machinery.

- Attention to Detail: Precise measurement and alignment are crucial in this profession, so strong attention to detail is essential.

- Physical Stamina: Millwrights often work in physically demanding environments and must be able to lift heavy objects and stand for long periods of time.

- Technical Knowledge: Familiarity with welding, rigging, and various hand and power tools is necessary for the millwright profession.

- Problem-Solving Abilities: As equipment malfunctions occur, millwrights must be able to quickly identify and resolve issues to ensure smooth operations.

Job Outlook and Salary

The millwright profession offers promising job prospects and competitive salaries. According to the U.S. Bureau of Labor Statistics, employment for millwrights is projected to grow by 8 percent from 2020 to 2030, which is faster than the average for all occupations. This growth can be attributed to the increasing need for machinery installation and maintenance in industries such as manufacturing, construction, and renewable energy.

| Median Annual Wage (2020) | Top 10% Earned (2020) |

|---|---|

| $54,920 | $86,840 |

As a millwright gains experience and expertise, they can expect their earning potential to increase. It is worth noting that specific industries and geographic locations can also influence salary levels within the profession.

Conclusion

In conclusion, millwrights play a crucial role in industries across the board, ensuring that machinery and equipment are installed, maintained, and repaired effectively. They possess a unique combination of technical expertise, mechanical skills, and problem-solving abilities that make them invaluable assets to any organization.

Throughout this article, we have explored the various aspects of the millwright profession, from their responsibilities and required education and training, to the essential skills and qualities they must possess. We have also discussed the diverse career paths and exciting opportunities available within the millwright industry.

If you are considering a career as a millwright, it is essential to understand the importance of continuous learning and professional development. The field is constantly evolving, with new technologies and techniques emerging. Therefore, it is crucial to stay up-to-date with the latest advancements to maintain your competitive edge.

Moreover, it is crucial to seek apprenticeship opportunities and gain hands-on experience in the field. This will not only enhance your practical skills but also provide you with valuable networking contacts and potential job opportunities.

Lastly, always remember to work with dedication, precision, and adherence to safety regulations. Safety is paramount in the millwright profession, and maintaining a strong commitment to safety will help you build a solid reputation and ensure the well-being of yourself and those around you.

In conclusion, a career as a millwright offers a promising future filled with challenges and rewards. Whether you choose to work in manufacturing, construction, or any other industry, the skills you develop as a millwright will always be in demand. So, take the first step towards this versatile trade and embark on a fulfilling and successful journey as a millwright.